The RO water plant is applying for producing various kinds of product or drink water.

The RO water plant is applying for producing various kinds of product or drink water.

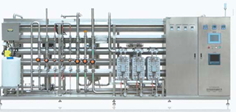

The raw water(spring water, mountain water, deep well water as raw water source) is pumped into the raw water tank through a water pump, and the large particles and impurities in the water are filtered out through preliminary filtration (silica sand, activated carbon filter and resin softener), and then use the RO reverse osmosis device or UF ultrafiltration device to remove microorganisms in the water. At last UV/Ozone sterilizer will sterilize the drinking water and store it in a pure water tank.

The preform is blown into a bottle by the bottle blowing machine, and sent to the bottle washing, filling and capping unit through the air conveyor. The water in the raw water tank is sent to the filling machine liquid tank through the pump, and the filling machine starts the bottle washing, filling and capping. Then full bottled water will be transported to the belt conveyor and use the bottle dryer to blow water drops on the surface of the bottle, after that, the bottle can be labeled and date coded. At last, the bottled water will be packed into PE film shrink package or carton box and stocked in the warehouse.

Water Production Line Process Description

a) The bottled water production line includes water treatment system, blowing bottle system, bottled water filling system, bottle labeling and packing system.

b) The whole production line is suitable for glass bottles or PET bottle filling according to clients’ demand.

c) We use the RO membrane to produce pure water and use the ultra-filtration membrane to generate natural mineral water.

d) The production line is flexible and fully customized, we can make it fully automatic with central control system or semi-automatic according to client’s budget and labor cost.

e) Suitable bottle size isφ50-100mm and H90-310mm, and if the bottle is beyond this size, we also have a customized filling machine.

f) The bottled water production machinery adopts food-grade SUS304 material, which can ensure the hygiene condition with the food field.

g) Water filtration membrane use imported GE, DOW, HYDECANME brand, it can fully guarantee the high-quality water after filtration.

h) Bottle water filling precision is controlled by a mechanical cam or flowmeter, the variation is ≤±2mm

i) The whole production line is controlled by the electronic control system, which can guarantee all equipment is running with synchronous and the efficiency is more than 95%.

j) Bottle label machine can be chosen from sleeve label machine, stick label machine or OPP label machine according to client bottle type and budget.

k) Bottle packing can be PE film packing or carton box packing, which is fully flexible.

l) PE screw caps, sport caps, aluminum caps are available for the bottled water.

The RO water production line including

* Raw water storage tank

* Raw water pump

* Sand filter (Multi-media)

* Active carbon filter

* Water softener

* Micro filter

* High pressure pump

* Hollow fiber ultra-filter

* Sterilizer (U.V or Ozone)

* Water tank

* Filling and packing machine

Water plant technical parameters

Capacity | From 50KG/Hour up to 50,000 KG/Hour |

Plant Automation Level | Manual, Semi-Automatic, Automatic, MES |

Products | Soft water, RO water |

Product package | PET, Carton, Drum etc. |

Contact: Foster

Phone: 0086-18616029030

E-mail: sales@oregenpak.com

Add: Jiading Zone, Shanghai, P.R.C