Milk Powder Handling Solution

Milk powder is defined as a milk product obtained by the extraction of water from milk. By removing moisture, the potential for microbial growth is reduced. As a result, milk powder provides transportation, storage convenience and shelf life benefits not found in liquid milk. Milk powder usually provides a lower cost milk alternative to liquid milk and has many applications.

Milk powder is defined as a milk product obtained by the extraction of water from milk. By removing moisture, the potential for microbial growth is reduced. As a result, milk powder provides transportation, storage convenience and shelf life benefits not found in liquid milk. Milk powder usually provides a lower cost milk alternative to liquid milk and has many applications.

Milk powder is often a very highly processed product that requires special treatment during handling. Highly fat-enriched milk powders may leave a product buildup in the convey line, which could affect the quality of the end product and will also create hygienic risks. Milk powders readily take up moisture from the air, leading to agglomerations in the convey line, as well as a rapid loss of product quality. The fat in milk powder can react with oxygen in the air to give off-flavors, especially at higher storage temperatures.

- Pneumatic conveying technologies

Pneumatic conveying has fewer moving parts and greater flexibility for plants with changing needs. Enclosed pipelines protect the material from contamination and virtually eliminate degradation of the product into smaller particles that can present a dust hazard. Pneumatic conveying also integrates filtration while delivering materials to their destination. Sugar refineries are finding they can also utilize this method to increase safety and cleanliness in their facilities.

- Dust collection

It is important that sugar handling facilities employ dust collection systems that are uniquely designed according to plant specifications and also have the benefits of:

a) Limiting emissions

b) Being specifically designed for ease of maintenance

c) Accounting for critical moisture concerns in the environment

d) Including cleanout or inspection opening in ductwork

- Explosion mitigation

There are three primary methods of explosion protection: venting, containment and suppression. Each of these methods of explosion protection offer varying degrees of cost and flexibility depending on the enclosure and its location.

A dust collection system alone does not keep a plant dust-free. Housekeeping must be a part of any good dust collection plan or design. Schenck Process central vacuum systems are an effective way to clean industrial environments that will minimize recontamination and the labor costs of housekeeping.

- Precise feeding

The feeder features the unique ability to disassemble, clean, reconfigure or service from the non-process side. Offered in three model sizes with either a flexible hopper or in all stainless steel, the versatility makes it a favorite for sugar processors.

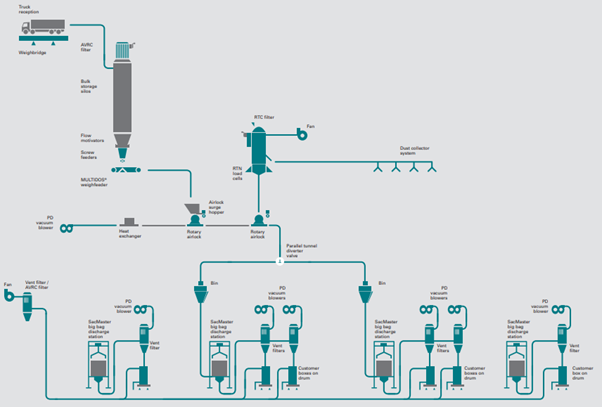

Milk Powder Handling General Process

Benefits of Milk Powder Handling Solution:

* Totally enclosed system

* Smaller footprint

* Significantly minimized degradation

* Few moving parts

* Reduced installation costs

* Lower maintenance costs

Contact: Foster

Phone: 0086-18616029030

E-mail: sales@oregenpak.com

Add: Jiading Zone, Shanghai, P.R.C